Welding Accessories

-

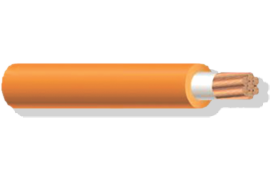

Copper Welding CableThese Welding Cables are used for the transmission of high currents from the electric welding machine to the welding tool. These are suited for flexible use under rough conditions such as on conveyor systems, assembly lines, machine tools, ship, building, motor car manufacturing and in manually and automatically operated line, spot welding machines.

Copper Welding CableThese Welding Cables are used for the transmission of high currents from the electric welding machine to the welding tool. These are suited for flexible use under rough conditions such as on conveyor systems, assembly lines, machine tools, ship, building, motor car manufacturing and in manually and automatically operated line, spot welding machines.

-

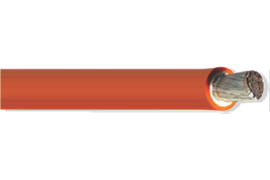

Aluminium Welding CableAluminum welding cables which are used for secondary side connection of power sources for hand or automatic metal-arc welding for secondary voltage typical of welding equipment. They are used in dry, wet and oil environments. Maximum permissible conductor temperature goes to 90°C.

Aluminium Welding CableAluminum welding cables which are used for secondary side connection of power sources for hand or automatic metal-arc welding for secondary voltage typical of welding equipment. They are used in dry, wet and oil environments. Maximum permissible conductor temperature goes to 90°C.

-

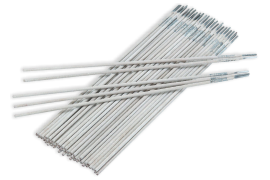

Welding ElectrodesIn arc welding an electrode is used to conduct current through a work piece to fuse two pieces together. Depending upon the process, the electrode is either consumable, in the case of gas metal arc welding or shielded metal arc welding, or non-consumable, such as in gas tungsten arc welding. For a direct current system the weld rod or stick may be a cathode for a filling type weld or an anode for other welding processes.

Welding ElectrodesIn arc welding an electrode is used to conduct current through a work piece to fuse two pieces together. Depending upon the process, the electrode is either consumable, in the case of gas metal arc welding or shielded metal arc welding, or non-consumable, such as in gas tungsten arc welding. For a direct current system the weld rod or stick may be a cathode for a filling type weld or an anode for other welding processes.

-

Welding HolderThese are used for holding welding material which is available in various specifications.

Welding HolderThese are used for holding welding material which is available in various specifications.

-

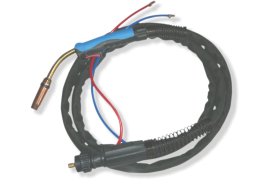

Tig Welding TorchA welding torch head is used to weld metals. It can be identified by having only one or two pipes running to the nozzle and no oxygen-blast trigger and two valve knobs at the bottom of the handle letting the operator adjust the oxygen flow and fuel flow.

Tig Welding TorchA welding torch head is used to weld metals. It can be identified by having only one or two pipes running to the nozzle and no oxygen-blast trigger and two valve knobs at the bottom of the handle letting the operator adjust the oxygen flow and fuel flow.

-

Mig Welding WireMetal Inert Gas are the strong, durable and reliable range of wires used for welding.

Mig Welding WireMetal Inert Gas are the strong, durable and reliable range of wires used for welding.

-

Mig Welding TorchLorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard.

Mig Welding TorchLorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard.

-

Arc Welding InverterA welding power supply is a device that provides an electric current to perform welding. Welding usually requires high current (over 80 amperes) and it can need above 12,000 amperes in spot welding. Low current can also be used; welding two razor blades together at 5 amps with gas tungsten arc welding is a good example.

Arc Welding InverterA welding power supply is a device that provides an electric current to perform welding. Welding usually requires high current (over 80 amperes) and it can need above 12,000 amperes in spot welding. Low current can also be used; welding two razor blades together at 5 amps with gas tungsten arc welding is a good example.

-

Tig/ Mig Welding InverterThere are basically 2 types of tig welders; rectifier, most common for many many years and inverters, new to market in past 15 years, but the fastest growing segment. A rectifier welder uses a transformer or coils to generate welding current. An inverter uses circuit boards to accomplish this. Rectifiers, especially in the larger size can be power mongers, while inverters accomplish the same job on far less power.

Tig/ Mig Welding InverterThere are basically 2 types of tig welders; rectifier, most common for many many years and inverters, new to market in past 15 years, but the fastest growing segment. A rectifier welder uses a transformer or coils to generate welding current. An inverter uses circuit boards to accomplish this. Rectifiers, especially in the larger size can be power mongers, while inverters accomplish the same job on far less power.

-

Tig Welding WireTIG Welding Wire is made of tungsten or a tungsten alloy, because tungsten has the highest melting temperature among pure metals, at 3,422 °C (6,192 °F). As a result, the electrode is not consumed during welding, though some erosion (called burn-off) can occur. Electrodes can have either a clean finish or a ground finish—clean finish electrodes have been chemically cleaned, while ground finish electrodes have been ground to a uniform size and have a polished surface, making them optimal for heat conduction. The diameter of the electrode can vary between 0.5 and 6.4 millimetres (0.02 and 0.25 in), and their length can range from 75 to 610 millimetres (3.0 to 24.0 in).

Tig Welding WireTIG Welding Wire is made of tungsten or a tungsten alloy, because tungsten has the highest melting temperature among pure metals, at 3,422 °C (6,192 °F). As a result, the electrode is not consumed during welding, though some erosion (called burn-off) can occur. Electrodes can have either a clean finish or a ground finish—clean finish electrodes have been chemically cleaned, while ground finish electrodes have been ground to a uniform size and have a polished surface, making them optimal for heat conduction. The diameter of the electrode can vary between 0.5 and 6.4 millimetres (0.02 and 0.25 in), and their length can range from 75 to 610 millimetres (3.0 to 24.0 in).

Gas Cutting Machine & Accessories

-

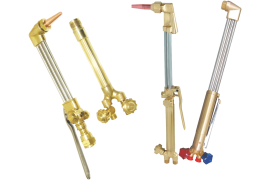

Cutting TorchA cutting torch head is used to cut materials. It is similar to a welding torch, but can be identified by the oxygen blow out trigger or lever.

Cutting TorchA cutting torch head is used to cut materials. It is similar to a welding torch, but can be identified by the oxygen blow out trigger or lever.

-

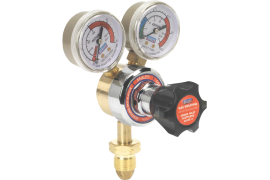

Acetylene RegulatorSolid brass construction with twin gauges, one showing the cylinder contents pressure and the second showing output pressure, calibrated in both Bar & Psi to enable an accurate flow setting.

Acetylene RegulatorSolid brass construction with twin gauges, one showing the cylinder contents pressure and the second showing output pressure, calibrated in both Bar & Psi to enable an accurate flow setting.

-

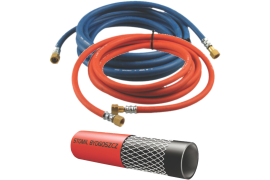

Gas Cutting HoseThese are the pipes which are specially designed for welding and cutting metals.

Gas Cutting HoseThese are the pipes which are specially designed for welding and cutting metals.

-

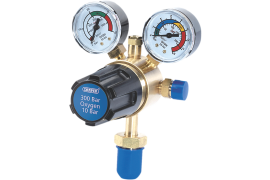

Oxygen RegulatorOxygen regulators will allow you to adjust your liter flow from 1-25 liters per minute depending on the liter flow you are prescribed the model regulator you are using.

Oxygen RegulatorOxygen regulators will allow you to adjust your liter flow from 1-25 liters per minute depending on the liter flow you are prescribed the model regulator you are using.

-

Tig TorchGTAW welding torches are designed for either automatic or manual operation and are equipped with cooling systems using air or water. The automatic and manual torches are similar in construction, but the manual torch has a handle while the automatic torch normally comes with a mounting rack.

Tig TorchGTAW welding torches are designed for either automatic or manual operation and are equipped with cooling systems using air or water. The automatic and manual torches are similar in construction, but the manual torch has a handle while the automatic torch normally comes with a mounting rack.

-

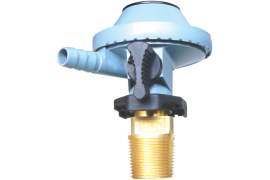

LPG RegulatorLPG regulators are designed to reduce pressure and control the incoming gas flow from your LPG tank or cylinder.

LPG RegulatorLPG regulators are designed to reduce pressure and control the incoming gas flow from your LPG tank or cylinder.

-

Flashback ArrestorA flashback arrestor or flash arrestor is a special gas safety device most commonly used in oxy-fuel welding and cutting to stop the flame or reverse flow of gas back up into the equipment or supply line and it prevents the user and equipment from damage or explosions.

Flashback ArrestorA flashback arrestor or flash arrestor is a special gas safety device most commonly used in oxy-fuel welding and cutting to stop the flame or reverse flow of gas back up into the equipment or supply line and it prevents the user and equipment from damage or explosions.

-

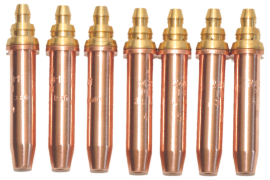

Cutting NozzleNozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition temperatures and direct the jet of oxygen onto the heated area to perform the cutting process.

Cutting NozzleNozzles are the vital component of flame cutting equipment. They provide the preheating flames to raise the steel to ignition temperatures and direct the jet of oxygen onto the heated area to perform the cutting process.

-

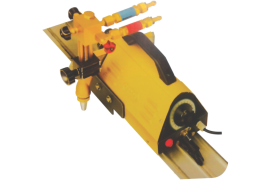

Pug Cutting MachineProfile Gas Cutting Machine helps a Fabricator in cutting production costs and increases efficiency. It is designed for heavy duty jobs and also for precision jobs. It works on single phase supply and is operated by 1/12 H.P. single phase motor. Machine is designed to operate on magnetic effect in the roller shaft of gear box. Movement of gas cutting nozzle is directly linked with magnetic roller shaft which results in fine cutting of metal.

Pug Cutting MachineProfile Gas Cutting Machine helps a Fabricator in cutting production costs and increases efficiency. It is designed for heavy duty jobs and also for precision jobs. It works on single phase supply and is operated by 1/12 H.P. single phase motor. Machine is designed to operate on magnetic effect in the roller shaft of gear box. Movement of gas cutting nozzle is directly linked with magnetic roller shaft which results in fine cutting of metal.